Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

Large delivery of BBC-R bearings. Updating the warehouse.

There are 0 items in your cart. There is 1 item in your cart.

Large delivery of BBC-R bearings. Updating the warehouse.

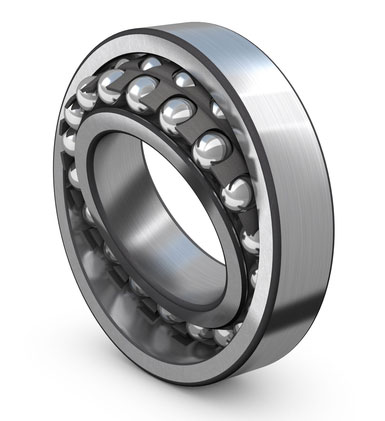

Bearing is a technical device, a part of the holder, supporting shaft or axle, fixing them in space, providing rotation, rolling or linear movement with the least resistance, as well as accepting and transferring the load to other parts of the structure.

Main types of bearings are: rolling and sliding bearings, gas-dynamic, hydrostatic magnetic bearings. Main types of bearings, used in engineering, are rolling and sliding bearings.

Some rolling bearings are made without the cage. These bearings have large number of rolling elements and greater capacity. However, the limit rolling speed of cageless bearings is much lower due to increased torques to rotation. Rolling bearings work mainly on rolling friction (there are only small losses on friction between the cage and rolling bodies) as compared to sliding bearings - reduce energy loss on friction and wearing. Capped rolling bearing (with protective washers) require virtually no maintenance (lubricant replacement), open - sensitive to foreign objects that may lead to rapid destruction of the bearing.

Bearings of regulated types can be classified by the following features:

1) the direction of sustained load according to the axis of the shaft;

On this basis bearings are divided into:

- radial bearings, which sustain only radial loads;

- angular contact ball bearings - designed to sustain combined loads, i.e. radial and axial simultaneously or in succession;

- thrust ball bearings can handle axial loads only.

2) the form of rolling elements

Bearings on this basis are divided into ball and roller bearings. Roller bearings can be cylindrical (short, long and needle), tapered, barrel-shaped (symmetrical and asymmetrical) and twisted.

3) the number of rows of rolling elements

3) the number of rows of rolling elements

On this basis bearings are divided into single-row, double-row, four- and multi-row.

4) self-aligning ability

By this constructive and operational grounds bearings are divided into self aligning (spherical) bearings and non-self aligning.

However, this classification is in some case conditional, since many types of bearings can meet different requirements. Therefore, there is no strict rules when selecting the type of the bearing. In addition, the machanician often has to make decisions in terms of conflicting requirements.

Thus, the size of the bearing on the outer and inner diameter must sometimes be chosen on the diameter of the bore of the housing or shaft. Limitations of space in the radial direction forces to use needle bearings, and sometimes even a set of needle roller with the cage, instead of the outer and inner rings housing spare parts of the machine. If space limitations in the axial direction use bearings with short cylindrical rollers.